About this deal

This stuff worked a treat," says Amy. "I had an old bottle lying around and sprayed it on. I waited just over five minutes and wiped and off it came. I was actually pleasantly surprised how easily it came off. Note, it did leave a bit of a chlorine smell like a swimming pool, which I didn't mind as it made the bathroom smell clean but it might bother some." What causes mould to grow on wood? Mould is dangerous and can cause all kinds of health issues, from skin rashes to breathing problems. For this reason, when removing mould spores from wood, protect yourself by wearing a mask, eye goggles and long-sleeved clothing —if you have protective clothing you could put on over your usual clothing it will be even better. You should also wear rubber gloves.

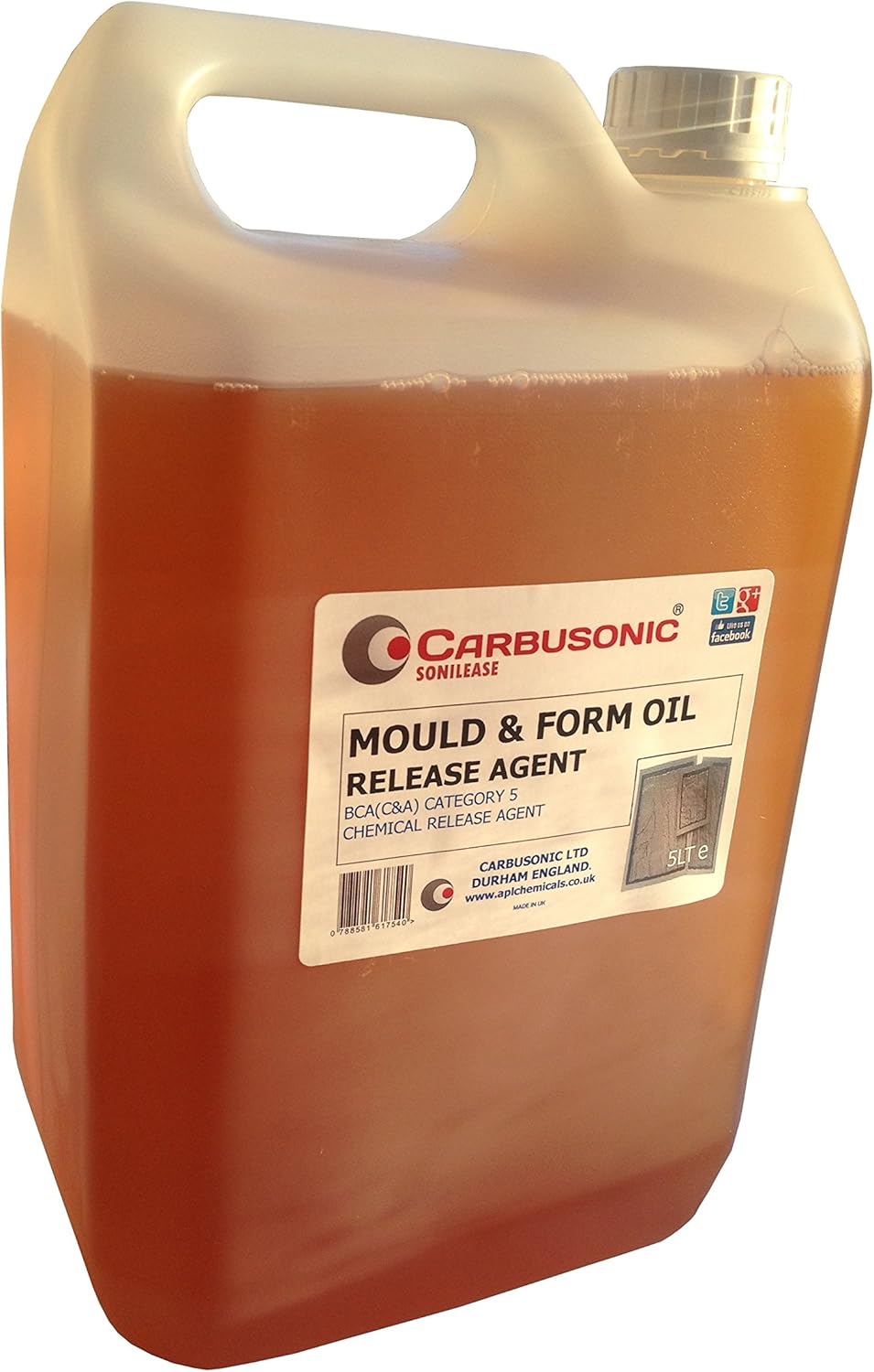

To avoid contamination of the reinforcement, it is advised that the shuttering oil is applied on the formwork before it is erected. These “Mould Oils” are applied to steel and timber formwork and falsework to reduce the cohesion between the curing concrete and the shuttering. Before the application of shuttering oil on the formwork, it is important to make sure that the surface of the formwork is clean of previous impurities. The shuttering oil is applied by spraying guns, rollers or by brushes. It is important to remove any excess oil on the surface of the formwork.There should not be any free oil on the wood surface. The form release agents that are good for wooden formwork are not always suitable for steel formwork. And hence the shuttering oil or form release agents should be chosen based on the type of formwork that is to be used for construction. Effects a clean positive release, which reduces labour costs, cleaning time and possible damage to formwork. This multi-reactive form release consists of an organic chemical that reacts with the alkali compounds found in concrete. It then releases a film that coats the form to which is it applied to prevent future bonding of concrete to its surface. Our mould oil has great performance characteristics that helps prevent bonding and long clean-up cycles.

Both baking soda and vinegar are a better choice for killing off mould than bleach. You can use them separately or combine them to create your own mould killer." The use of barrier paints extends the life of the formwork by producing a hard-wearing surface on the formwork. If barrier paints are not used, it is advised to use three coats of shuttering oil before the shuttering is used for the first time. Many new forms are not factory treated with oils, so for new or ‘unsealed’ timber formwork, pre-treatment is essential with two to three coats prior to use. This will extend the useful life of the form and help to standardise surface absorbency. For unsealed ply consideration could also be given to primary sealing with NORSEKEM SHUTTAWAX or NORSEKEM FORMSEAL PU1K sealer Mould oils come in diverse formulations tailored to specific applications and materials. Whether water-based, solvent-based, or silicone-based, each formulation offers distinct advantages depending on the type of mould and material being used. Applying mould oils is a flexible process that can be accomplished through various methods such as spraying, brushing, or wiping onto the mould surface. The choice of application method depends on factors like mould type, accessibility, and the consistency of the oil being used.

Mould Oil

Our Mould Oil helps ensure that formwork remains free of concrete deposits is therefore an essential task and an efficient and powerful cleaning agent is a vital product to get the job done. This is a water-based mould releasing agent which gives clean and stain free high-quality concrete. It is available in a sprayable form and ready to use as a direct application on required places. It should be applied in light film either by brush or mould oil sprayer. If it is over applied, excess oil should be drained before it dries. Pools of DSO cannot be allowed to dry as it causes surface retardation of concrete. Mould oils play an essential role in enabling efficient production processes, enhancing product quality, and extending the life of moulds in diverse industries such as manufacturing, construction, automotive, and plastics. What mould oils can you supply? The application of mould oils helps safeguard the mould surface against wear, corrosion, and the accumulation of deposits or residues from the materials being cast. Consequently, the oils contribute to prolonging the lifespan and reducing the need for frequent cleaning or repairs.

If you don't fancy making up your own solution and aren't anti-chemical, there are products available to buy that are designed specifically for removing mould from wood. Also Read: Types of Formwork (Shuttering) for Concrete Construction and its Properties Types of Shuttering oil: 1. De-Shuttering Oil (DSO) If the wood in question has been painted or stained, it is less likely that the mould you will be removing will have penetrated the timber, meaning removing it should be easier than if you were dealing with bare wood. The first is to use a solution made up from vinegar and water — in equal parts. Vinegar will not only get rid of the mould but it should also help eliminate or at the very least fade out, the stains. Use a spray bottle to apply the solution, allow it to sit for a couple of hours, then wipe the area down with a damp cloth or rag. sq. ft/USGal (17.7-36.8 sq.m/L), depending on the type and porosity of the form surface. Precautions

WB Emulsified Formwork Concrete Release Agent

Mould on bare wood can be harder to remove than that on painted wood —a light sanding after removal can really help. (Image credit: Getty) Which products remove mould from wood?

Condensation can be a major culprit when it comes to mould on timber. (Image credit: Getty) Removing mould from bare woodJust as with any type of mould in the home, the main culprits are too much moisture and damp in the air and poor ventilation. Where wood is located on a cold, external wall the problem may well be worse. Bare wood, being pretty porous, makes a great breeding ground for mould too, with no protective coating to prevent the mould from working its way into the grain. How can I prevent mould from returning? CMT Group ensures that you, our valued customer, enjoys your shopping experience as we strive to make your experience ‘hassle free’. Spraying is the ideal method of application. Use a Mesto sprayer that flows approximately 1 gallon per minute (suitable sprayers available from the accessories section below). Speed//STRIKE may also be applied by roller coating,mopping or brushing. A thin film should be applied for maximum economy and efficiency. Runs or puddles need to be brushed out. For metal forms, the best results are obtained with a spray-on 'fog' application of Speed//STRIKE. Coverage Work the solution into the wood, leave it to get to work for a hour or so then wipe away using a damp cloth. Rye Oil Ltd’s Mould Oil MD3B was originally designed for wood forms. It is a straight refined, pale, paraffin-base mineral oil (an oil-phased emulsion). This is capable of penetrating the wood while leaving the surface only slightly greasy to the touch with no free oil on the form.

Great Deal

Great Deal